In the fast-paced world of sheet metal fabrication, efficiency is key to staying competitive and reducing costs. At Greater Wisconsin Sheet Metal we understand the importance of optimizing the process to deliver high-quality results quickly and cost-effectively. Here are some great efficiency hacks that we’ve learned over the year, hopefully they will help you in your sheet metal fabrication operations.

Optimize Material Usage

Efficient material usage is a cornerstone of cost-effective fabrication.

- Nesting Software: Advanced nesting software helps minimize waste by strategically arranging parts on the sheet metal. This can be done on the water jet, plasma cutter, or any other tool that uses G-Code. This ensures maximum utilization of material, reducing scrap and saving costs. SigmaNEST, ProNest, and NestFab are all examples of nesting software.

Standardize Materials: By standardizing the types and sizes of sheet metal used, you simplify inventory management and reduce changeover times. This consistency allows for more predictable and efficient production runs. The secondary benefit of standardizing your materials is purchasing power. Buy more, spend less.

Invest in Modern Equipment

Upgrading to the latest equipment can dramatically improve fabrication speed and accuracy. There are no shortages of equipment manufactured for sheet metal fabrication, so do your diligence when selecting modern tooling.

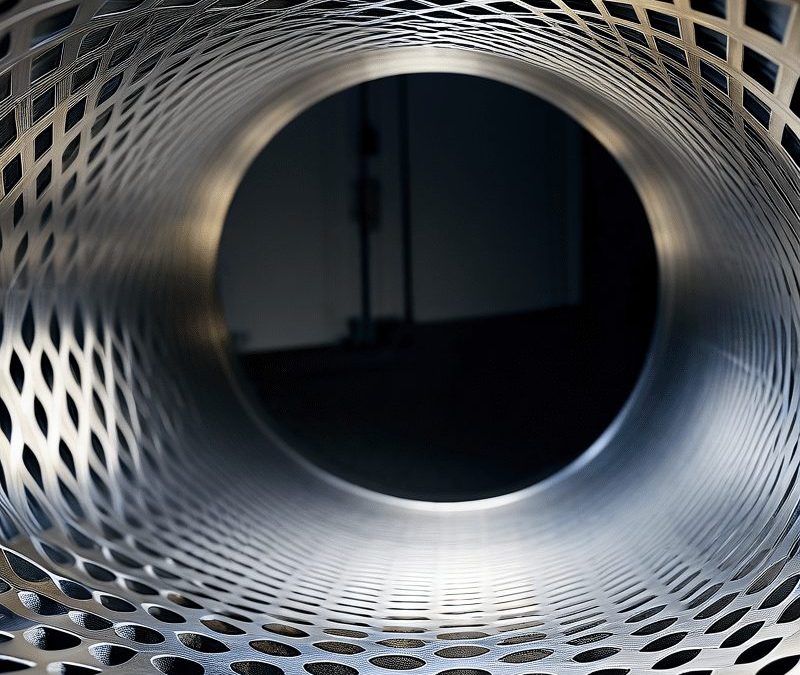

- Water Jet Cutting Machines: Water jet cutting offers precision and versatility, cutting through various materials with ease and leaving clean edges. This method is faster and more flexible than traditional cutting methods, making it ideal for complex shapes and thick materials.

- Automated Press Brakes: Automated press brakes enhance bending efficiency and consistency. These machines reduce manual intervention, increasing throughput and maintaining high quality.

Implement Lean Manufacturing Principles

Lean manufacturing principles help eliminate waste, streamline processes, and create a culture of safe work.

- 6S Methodology: Apply the 6S methodology (Sort, Set in order, Shine, Standardize, Sustain + Safety) to organize your workspace. A well-organized shop floor reduces clutter, improves workflow, and minimizes time spent searching for tools and materials.

- Continuous Improvement: Encourage a culture of continuous improvement. Regularly review and refine processes to identify and eliminate inefficiencies. Small, incremental changes can lead to significant long-term gains.

- Regularly Solicit Feedback: Encourage your metalworkers, purchasing people, and safety engineers to provide detailed feedback when possible. Nuggets will make you more efficient and the more feedback you get the more potential nuggets you’ll find.

Employee Training and Cross-Training

A well-trained workforce is essential for efficient operations. At Greater Wisconsin Sheet Metal our metal workers are cross trained in nearly every discipline we work in.

- Skill Development: Invest in regular training programs to keep your workforce updated on the latest techniques and technologies. Skilled employees can work more efficiently and produce higher-quality work.

- Cross-Training: Cross-train employees to perform multiple tasks. This flexibility allows you to reallocate resources as needed, reducing downtime, and ensuring continuous production. This is a key factor in being competitive in custom metal projects.

Use CAD/CAM Software

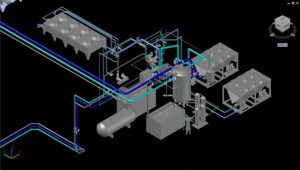

Leveraging CAD/CAM software can greatly enhance design and manufacturing efficiency. We also utilize BIM software when working with structural steel components for buildings to make sure the structure we’re building fits into the building we’re putting it in.

- Integrated Design and Manufacturing: CAD/CAM software integrates design and manufacturing processes, allowing you to create and simulate designs before production. This reduces errors and rework, saving time and material.

- Automation of Repetitive Tasks: Automate repetitive tasks like tool path generation to save time and reduce the potential for human error. Automation ensures consistency and precision in every job.

Preventive Maintenance

Maintaining your equipment is crucial for uninterrupted production.

- Regular Equipment Checks: Implement a preventive maintenance schedule to perform regular checks on your machines. Preventive maintenance helps avoid unexpected breakdowns and keeps your equipment running smoothly.

- Monitor Tool Wear: Regularly check and replace tools to maintain cutting precision and avoid costly errors. Keeping tools in optimal condition ensures consistent quality and reduces downtime.

Streamline Production Workflow

An efficient workflow is essential for maximizing productivity.

- Cellular Manufacturing: Arrange your workshop in a cellular layout where similar tasks are grouped together. This reduces movement and handling, streamlining the workflow and increasing efficiency.

- Just-in-Time Production: Implement Just-in-Time (JIT) production to reduce inventory costs and increase responsiveness to demand. JIT ensures that materials and components are available exactly when needed, minimizing waste and storage requirements.

Outsource Non-Core Activities

Focus on your core competencies and outsource specialized tasks.

- Subcontracting: Outsource non-core or highly specialized tasks to experts. This allows you to maintain focus on your primary operations and improve overall efficiency. Subcontracting can also provide access to advanced technologies and specialized skills.

Implement Quality Control Systems

Quality control is vital for maintaining high standards and reducing rework.

- In-Process Inspections: Conduct inspections during the fabrication process to catch errors early. In-process inspections help identify and correct issues before they become costly problems.

- Final Quality Checks: Perform comprehensive final checks to ensure that finished products meet quality standards. Thorough quality control ensures customer satisfaction and reduces the risk of returns.

Utilize Advanced Joining Techniques

Advanced joining techniques can enhance both speed and quality.

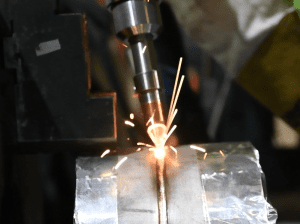

- Laser Welding: Laser welding offers precision and speed compared to traditional welding methods. It produces strong, clean welds with minimal heat distortion.

- Adhesive Bonding: Explore adhesive bonding for certain applications. Adhesive bonding can reduce the need for welding or riveting, offering a cleaner and sometimes faster joining method.

By adopting these efficiency hacks, you can significantly speed up your sheet metal fabrication processes while maintaining high-quality standards. Continuous improvement, staying up-to-date with the latest technologies, and fostering a skilled workforce are key to achieving sustained efficiency gains.