The sheet metal fabrication industry is amid exciting changes, driven by innovations in technology and material science. At Greater Wisconsin Sheet Metal (GWSM), we are committed to staying ahead of these trends, constantly refining our processes to meet the needs of our clients. In this post, we’ll explore the key trends shaping the future of sheet metal fabrication and how GWSM is leveraging advanced tools and techniques to deliver high-quality, eco-friendly solutions. Let’s dive into what’s next for the industry.

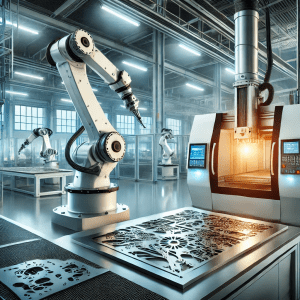

Automation and Robotics in Fabrication

Automation is playing a significant role in modern sheet metal fabrication, allowing for greater precision, faster production, and reduced waste. Tools like CNC (Computer Numerical Control) machines make it possible to fabricate complex parts more efficiently, and the use of robotics helps reduce the need for manual labor.

Automation is playing a significant role in modern sheet metal fabrication, allowing for greater precision, faster production, and reduced waste. Tools like CNC (Computer Numerical Control) machines make it possible to fabricate complex parts more efficiently, and the use of robotics helps reduce the need for manual labor.

How GWSM is Leveraging Automation:

Greater Wisconsin Sheet Metal uses CAD like software to run its waterjet cutter, plasma cutter, and laser engraving tool to ensure precision and efficiency in every project. These automated systems allow us to work quickly and accurately, whether it’s for large-scale production or customized, small-batch orders.

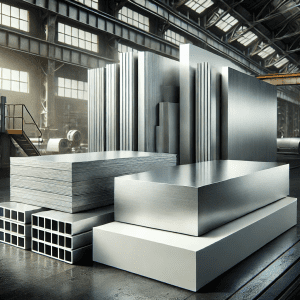

Advanced Materials: Lightweight and High-Performance Solutions

As industries demand more durable and lightweight materials, sheet metal fabricators are increasingly working with advanced materials that can perform in harsh environments. For many projects, stainless steel, aluminum, and high-density rigid PVC are becoming go-to materials due to their corrosion resistance and strength-to-weight ratio.

As industries demand more durable and lightweight materials, sheet metal fabricators are increasingly working with advanced materials that can perform in harsh environments. For many projects, stainless steel, aluminum, and high-density rigid PVC are becoming go-to materials due to their corrosion resistance and strength-to-weight ratio.

Our Material Expertise:

At GWSM, we frequently work with stainless steel, aluminum, and high-density rigid PVC to provide our clients with solutions that meet rigorous performance standards. These materials allow us to deliver durable, long-lasting products across industries such as construction, manufacturing, and industrial applications.

Sustainability and Eco-Friendly Practices

Sustainability is an essential consideration for modern sheet metal fabrication. As businesses look for ways to reduce waste and energy consumption, eco-friendly practices are becoming a priority. The use of nesting techniques to optimize material usage and recycling scrap metal are key strategies for reducing environmental impact.

GWSM’s Commitment to Sustainability:

Greater Wisconsin Sheet Metal is proud to implement eco-friendly practices in our operations. We utilize advanced nesting techniques to minimize material waste and recycle all used materials. Additionally, our facility is equipped with geothermal heating and cooling, which helps us save 30-40% on energy costs, making our operations more sustainable and cost-effective.

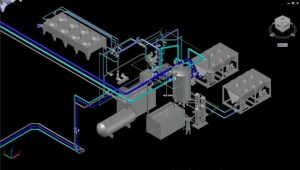

Advanced Software and Digital Integration

The integration of advanced software into the sheet metal fabrication process is transforming how projects are designed and executed. CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and Building Information Modeling (BIM) tools allow fabricators to streamline workflows and ensure accuracy from the initial design phase to final production.

The integration of advanced software into the sheet metal fabrication process is transforming how projects are designed and executed. CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and Building Information Modeling (BIM) tools allow fabricators to streamline workflows and ensure accuracy from the initial design phase to final production.

How GWSM Uses Cutting-Edge Software:

At Greater Wisconsin Sheet Metal, we use CAD, CAM, and BIM tools to design and execute projects with precision. Our software suite includes industry-leading platforms such as SolidWorks and Autodesk, enabling us to efficiently design complex systems and ensure seamless production.

Customization and Small-Batch Production

As industries increasingly seek custom, specialized solutions, the ability to produce tailored components and small-batch runs is becoming more important. Advances in fabrication tools allow companies to offer flexibility and fast turnaround times without significantly increasing costs.

As industries increasingly seek custom, specialized solutions, the ability to produce tailored components and small-batch runs is becoming more important. Advances in fabrication tools allow companies to offer flexibility and fast turnaround times without significantly increasing costs.

Our Approach to Custom Projects:

GWSM specializes in custom fabrication and recently completed a two-off project for a large venturi air scrubber, which had a 20-foot diameter and included a steel base to hold the scrubber vertically. Projects like these demonstrate our ability to take on unique, complex jobs with precision and care.

Conclusion

The future of sheet metal fabrication is filled with opportunities for innovation, from automation and advanced materials to sustainability initiatives and digital integration. Greater Wisconsin Sheet Metal is at the forefront of these trends, combining innovative technology with eco-friendly practices to deliver top-tier results for our clients. Whether it’s large-scale projects or specialized custom solutions, we’re ready to build something together.