In industrial projects, a one-size-fits-all solution often doesn’t work. That’s where custom fabrication shines, providing tailored solutions that meet unique specifications and challenges. At Greater Wisconsin Sheet Metal, our commitment to custom fabrication helps us handle everything from standard tasks to complex custom jobs with precision and efficiency.

Custom Cutting Techniques

Plasma Cutting: Our plasma cutting services are central to our fabrication process, offering unmatched speed and precision. Perfect for both light and heavy gauge materials, plasma cutting allows us to cut through various metals quickly and precisely. This technique is fast and cost-effective, making it ideal for time-sensitive industrial applications. This method is perfect for items that don’t need an extreme level of definition, with metals that aren’t prone to heat warpage.

Waterjet Cutting: When projects require precision beyond metals, our waterjet cutting services are invaluable. This method excels with its versatility, cutting through just about anything, especially materials like metals, composites, and ceramics. Waterjet cutting is excellent for designs that need intricate details and tight tolerances without the risk of warping or material distortion.

especially materials like metals, composites, and ceramics. Waterjet cutting is excellent for designs that need intricate details and tight tolerances without the risk of warping or material distortion.

Precision Bending and Forming

Our facility features advanced bending machines, such as press brakes and roll benders, allowing us to shape metal sheets and plates accurately. This precision is crucial in ensuring that each component fits perfectly in complex assemblies, important for maintaining structural integrity and functionality.

Expert Welding Services

Welding requires skill and precision. At Greater Wisconsin Sheet Metal, we provide various welding techniques—MIG, TIG, and Laser welding—to suit different types of metals and project needs. Our certified welders ensure each join is strong and meets both strength and appearance standards. We are certified to weld high pressure piping and vessels.

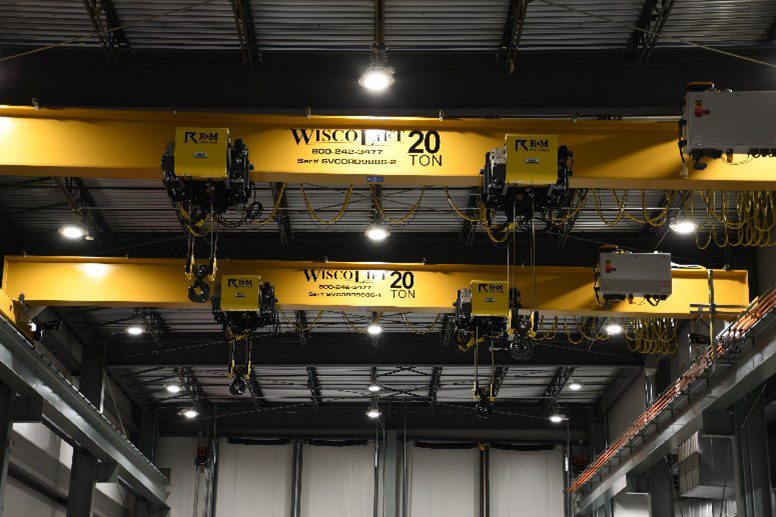

Capability in Handling Heavy and Large-Scale Projects

Handling heavy and large projects demands technical skills and strong logistics. Our team has extensive experience in managing large-scale fabrications from design to installation. We are proud of our ability to handle complex projects that meet all logistical and quality standards, evident in our successful large component and structure installations.

Creating Unique Items

Each project has unique challenges and requirements. We meet these with our customized solutions. Whether creating intricate architectural details or essential industrial components, our approach combines creativity with technical skill to solve specific problems and deliver customized solutions. Our work includes uniquely designed metalworks that are functional and visually appealing, showing our ability to innovate.

Conclusion

At Greater Wisconsin Sheet Metal, we are dedicated to excellence in every project. Our wide range of custom fabrication services ensures we can meet your specific needs efficiently and accurately. We encourage you to bring your unique challenges to us. Let’s work together to create something outstanding.